Expanded Metals vs. Perforated Metals – Costs, Benefits and Analysis

Architects and building contractors are often faced with many challenging decisions when choosing the right materials for a job. Different types of metals, materials and fabrication methods affect the performance of a structure or facility hugely, and structural sheet metal is no exception. While perforated metals and expanded metals are similar and have some overlapping applications, engineers understand that their capabilities are very different. Not only are perforated and expanded metals separated by their application industries, but by their fabrication methods and cost as well.

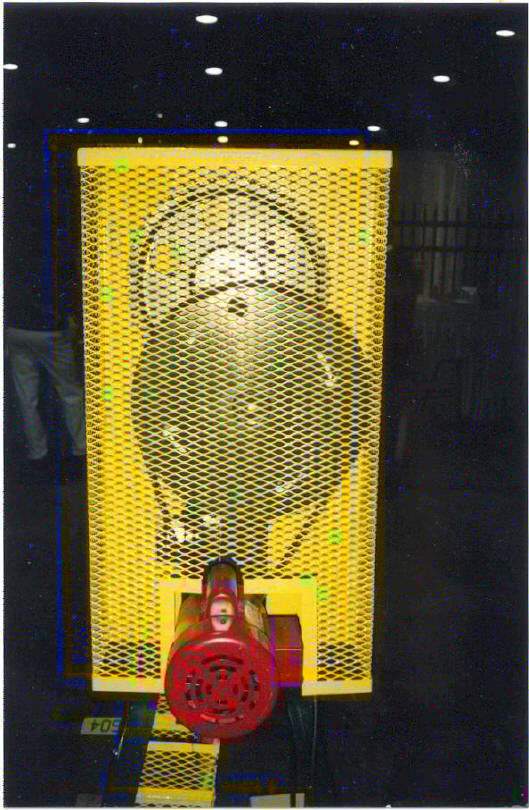

Perforated metal seems to be the industry standard for architectural applications such as building facades, fences and partitions. Because perforated metals are punched and cut, dies can be designed to cut patterned shapes into sheet metal for a variety of purposes, both decorative and functional. The shape of metal perforations can determine a material’s usefulness for blocking microwaves, sound waves or light; perforated metals are used in all these industries. Next time you warm up some leftovers, take a look at your microwave door. See that filter in the glass? That’s a piece of perforated metal blocking microwaves from coming through the door.

Soundproofing and acoustical enhancement is another important application for perforated metal, which is capable of muffling, blocking or softening sound within structures that are too large to soundproof with foam acoustic panels. Theater lights and laboratory lights are often filtered and diffused with perforated metal, and large office buildings or corporate structures can benefit from an interior perforated wall panel’s decorative and sound muffling properties.

Aside from architectural uses, perforated metal functions in a number of filtering applications when fabricated as perforated tubes. These are often used in inline processing to filter fisheyes or other agglomerates during pharmaceutical, chemical or food processing.

Expanded metal sheets, while capable of many of these applications (except soundproofing), excel in a different area entirely. The stair treads, walkways, catways and floor grating found so commonly in industrial facilities, construction sites and even many commercial buildings are made from industrial expanded metal. Expanded metals are capable of far greater structrual strength than perforated metals; unlike perforated metals, expanded metals are slit and stretched, creating a pattern of three dimensional structures, although expanded metal may also be rolled into a two dimensional sheet. This slitting and stretching process sets expanded metals apart from perforated metals in cost and fabrication time. Because expanded metals are slit and stretched, there is virtually no waste material, significantly lowering fabrication costs. It’s also a fairly quick process, making custom expanded metal stair tread orders fast and cost-effective.

To wrap up, let’s look at a summary of expanded and perforated metals as compared to one another:

| Expanded Metal | Perforated Metal | |

|---|---|---|

| Cost | Low | Mid to High |

| Fabrication Method | Slitting and stretching; rolling for 2 dimensional sheets | Punching |

| Waste Material | Little or none | Relatively high, depending on hole diameter |

| Texture | 2 dimensional or 3 dimensional with surface grip capabilities | 2 dimensional |

| Structural Stability | Excellent | Low to moderate |

| Design Flexibility | Moderate | High |

| Architectural Applications | Stair treads, floor grating, walkways, fencing, doors, furniture | Decorative walls, barriers |

| Technical Applications | Light diffusing | Sound barriers, noise proofing, electronic housing ventilation, computers, speakers |

| Filtering Applications | Large process particles, industrial processing | Microwaves, electromagnetic waves, sound waves, fine process liquids, gas flow control |

Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services