A Primer on Dense Phase Pneumatic Conveying Systems

by Dynamic Air, Inc.

Dynamic Air Inc., a major leader in the dense phase pneumatic conveying industry, is a specialist in the pneumatic conveying of dry, bulk solids. Applications range from food to poison, from light fumed silica to heavy powdered metals. However, all of these applications have one thing in common, the necessity to control the conveying velocity in order to control particle degradation, conveying pipe wear, minimize air consumption, or eliminate pipe line plugging.

What is Pneumatic Conveying?

Pneumatic conveying is nothing more than creating a pressure differential along a pipeline and moving a bulk material along with the air as the air moves towards the area of lower pressure. This can be done with a vacuum inducer, or with compressed air being injected into one end of or along the pipeline.

Dilute Phase vs. Dense Phase Pneumatic Conveying

The two most distinct categories of pneumatic conveying can be described as either low pressure (dilute phase) or high pressure (dense phase) systems.

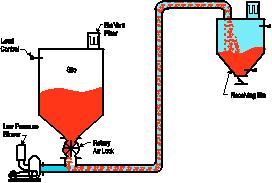

The first category, the low pressure system, referred to as a dilute phase pneumatic conveying system, utilizes air pressure under 15 PSIG. These systems use either positive or negative pressure to push or pull material through the conveying line at relatively high velocities (see Figure 1). They are described as low pressure/high velocity systems which have a high air to material ratio.

Figure 1 – Dilute phase conveying system.

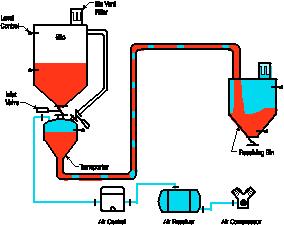

The second category, the high pressure system, generally referred to as a dense phase pneumatic conveying system, utilizes air pressures above 15 PSIG. These systems utilize positive pressure to push materials through the conveying line at relatively low velocities (see Figure 2). They are described as high pressure/low velocity systems which have a low air to material ratio.

By definition, dense phase pneumatic conveying simply means using a small amount of air to move a large amount of bulk material in closely-associated slugs through a conveying line, much like extruding. Unlike dilute phase conveying systems that typically use larger amounts of air to move relatively small amounts of material at high velocities in suspension, dense phase offers the enormous advantage of efficiently “pushing” a much denser concentration of bulk solids at relatively low velocities through a conveying line.

Pneumatic conveying systems for bulk materials

Many material handling plants need to transfer large quantities often times over long distances. As a result, the power consumption of the conveying system is of prime importance. In pneumatic conveying, the power consumption is a function of the system design, transfer rate, and conveying length. Therefore, a conveying system that transfers 100 tons per hour of a bulk material over a distance of 200m will use about the same power as a system of the same design and conveying the same material at a rate of 200 tons per hour over a distance of 100m. So, from this it is evident that the length of a pneumatic conveying system has the same impact on power consumption as rate does.

Traditionally, bulk materials have been conveyed by inefficient pneumatic conveying systems, and modern material handling plants have a need for more efficient conveying systems to reduce power costs. However, power consumption savings do not stop with the cost of electricity. There are also many other benefits associated with lower power consumption. First, if a conveying system uses less power, there is less maintenance. Compare the Formula 1 race car to the economy car. Which car needs more maintenance? Which car gets more life from the tires? From the engine? Pneumatic conveying systems are no different. If two pneumatic conveying systems must convey the same material over the same distance, and one system uses less power than the other, then the lower power consumption system will have less wear, will need a smaller dust filter, and will create less pollution.

A new generation of dense phase pneumatic conveying systems

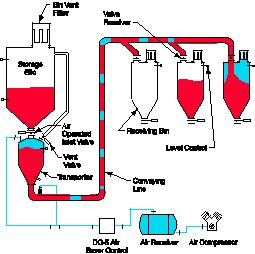

Through relentless research and development, a new dense phase pneumatic conveying concept was born, the Dense Phase Full Line Concept with DC-5 Air Saver technology (see Figure 3). The DC-5 Air Saver technology is a means by which compressed air is automatically injected along the conveying pipe in small amounts in response to the conditions inside the conveying pipe.

Figure 3 – Full Line Concept™ conveying system with DC-5 Air Savers

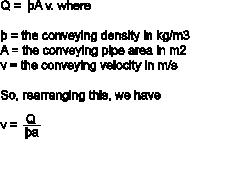

Figure 3 – Full Line Concept™ conveying system with DC-5 Air SaversThis new technology reduces the air consumption to the absolute minimum by allowing the system to convey with the conveying pipe line at maximum density. This means that the conveying pipe is as full as possible with cement, and not flowing dilute with cement as a vacuum cleaner would. This maximum density conveying technique has three main advantages. First, because the conveying pipe line is so dense with the bulk material, the air cannot “slip” past the bulk material, which is a common inefficiency in pneumatic conveying systems. If we eliminate the slip, we improve efficiency. Second, when the conveying pipe is at maximum density, only a small percentage of the particles are in contact with the conveying pipe at any given time. The majority of the particles are in the interior of the pipe, therefore not abrading the pipe. So, this significantly decreases pipe wear. Third, by increasing the pipe density, the conveying velocity can be decreased for a given transfer rate and pipe diameter. The transfer rate, Q, in kg/s can be expressed as:

Velocity control provides many benefits

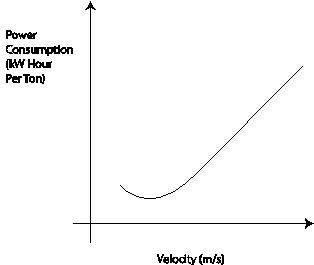

Velocity control is another byproduct of this new technology. Because compressed air is injected along the conveying pipe, the DC-5 Air Saver technology can provide very accurate control of the conveying velocity. This is important for three reasons. First, similar to a car, energy efficiency in a pneumatic conveying system is velocity dependent. In general, the slower the conveying velocity, the better the air efficiency (see Figure 4). Second, pipe wear increases with velocity, and is proportional to the velocity cubed. So, if the velocity is doubled, the wear increases eight times. So, even small reductions in velocity can provide dramatic improvements in pipe wear. Third, and maybe the least intuitive is that a slower conveying velocity reduces the chance of convey pipe plugging. Most would think the opposite. After all, if you don’t want your car to get stuck in the mud, you had better go very fast through it, right? The opposite is true for pneumatic conveying systems. The reason is because a pneumatic conveying system must change directions through the use of pipe bends. When the conveyed material reaches the pipe bend, it decelerates due to the friction of the bend. If the material if moving too fast when entering the bend, it will decelerate rapidly, causing the conveyed material to compact like a brick, and form a plug. However, if the conveying velocity is very slow, the deceleration will be negligible. I will provide a simple illustration of this. At the speed of a Formula 1 race car, they need to brake hard at every turn. However, if you rode a bicycle on the same track you would hardly notice the turn since the bicycle speed is so slow. This is what we are trying to achieve with the pneumatic conveying system.

Reliability is improved

Finally, the DC-5 Air Saver technology has provided another very significant benefit, reliability. Because the compressed air is injected along the conveying pipe line, should the system tend to block or plug, the DC-5 Air Saver technology automatically adjusts the compressed air distribution to break the plug. The system automatically reacts to the conveying conditions and can provide tremendous leverage to dislodge a blockage at any point along the conveying pipe. Although most tend to focus on the air efficiency aspect of the conveying system, reliability is maybe of even more importance. A robust conveying system will allow the conveying system to function even when the material to be conveyed is not ideal.

How does the new Full Line Concept system with DC-5 Air Saver technology work?

A series of air inlet devices, called DC-5 Air Saver controls, are mounted on the conveying line. Each DC-5 Air Saver control allows part of the conveying air to enter the conveying line. The DC-5 Air Saver controls dual purposes are to control the conveying velocity as well as prevent system plugging. In effect, the Air Saver control will reduce the total resistance of the system. The effect of each Air Saver control provides an incremental force. The total number of Air Saver controls acting in unison produces a significant total force.

The Full Line Concept system (with the DC-5 Air Saver controls) operates as follows: Material fills the transporter from a storage silo through an inflatable seated butterfly valve. Displaced air is vented up through a vent valve to allow easier filling. Once the transporter is filled, as signaled by a high level control or weighing device, the inlet and vent valves close and seal. Then the outlet valve opens and compressed air is introduced into the transporter to displace the conveyed material. All other compressed air used for conveying is added through the DC-5 Air Saver controls spaced along the conveying line.

When the transporter is completely empty, as signaled by a low level control in the transporter, the compressed air is turned off and material stops in the conveying line. Because the conveying line does not purge itself clean, the high velocity normally seen in the conventional type system during the purge cycle is totally eliminated, thus making the Full Line Concept system ideal for abrasive and/or fragile materials.

Also, since the line always remains full, there is no time lost in emptying and filling the conveying line. Air consumption is drastically reduced making the Full Line Concept system ideal for long conveying line distances and where a single material is being conveyed. The system can, however, operate as a conventional system when the conveying line needs to be purged for maintenance or if product changeover is necessary.

Summary

Modern material handling facilities have become more concerned with the energy efficiency as well as the reliability of their conveying systems, they will demand more advanced conveying systems to reduce their operating costs. Therefore, a supplier of pneumatic conveying systems today has to provide a high technology solution to move material reliably and with the minimum amount of compressed air. Although slightly more costly, the savings in operating costs often pay for the advanced technology pneumatic conveying system in just a few years.

Dynamic Air Inc.

St. Paul, MN 55110

Phone: 1 651 484-2900 – Fax: 1 651 484-2015

email: info@dynamicair.com

www.dynamicair.com

Dynamic Air Ltd.

Milton Keynes, United Kingdom

Phone: 44-1908-622344

Fax: 44 (0)1908-646633

e-mail: sales@dynamicair.com

Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services