Wire Rope: A Rock Climber’s Best Friend

by Jenny Knodell, IQS Editor

For the past year, my younger brother has been backpacking around New Zealand, sleeping in a tent, working on farms and climbing mountains. From the pictures I’ve seen, it’s been an amazing adventure in one of the most naturally beautiful places on Earth. The older sister in me, though, is always a little bit worried. I imagine him scaling the sides of steep rock formations or climbing his way to the top of Mount Cook, and I realize how much more of a thrill seeker he is than me. While I would prefer he take up a more relaxing outdoor sport like fishing, the fact that he’s well equipped for belaying allows my mind to rest easy. Instead of relying on a good grip and foot holding, most rock climbers these days use an effective system consisting of a harness, pulley and belay loop, which are all attached to a sturdy climbing rope. Belaying ensures the climbers won’t fall very far in case they slip off a rock.

The most important single piece of gear for rock climbers is the rope. It can be made of nylon, rubber or wire. Wire rope is the first choice for many climbers because it’s reliable, able to handle hundreds of pounds of weight and isn’t likely to fray. Most wire rope made for rock climbing and scaling is thin, about 1/5 of an inch. This type is sometimes called wire cable and is the first choice for rock climbers because it’s less bulky and more flexible, and still able to hold almost 500 pounds of weight. These ropes are more than enough to handle my brother and all his gear, and last a very long time without much maintenance. If wire rope is used as aircraft cables to handle large air planes, in weight lifting systems and in bridge construction to transport huge heavy steel beams, then I’ll trust it when it comes to keeping my brother safe.

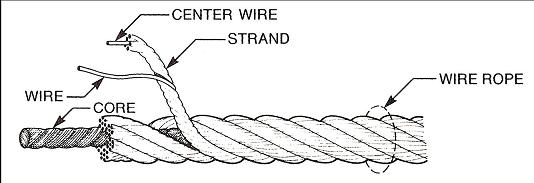

Why is wire rope so strong? It’s composed of 3 parts—wires, strands and a core. The basic unit is a single wire, which is a very thin piece of extruded metal like steel or aluminum. Anywhere from 2 to 40 of the wires are twisted together to form strands. The strands then wrap themselves around a core, which is a thicker, solid piece of cotton, plastic or wire. You wouldn’t think so, but wire ropes are technically considered simple machines because they are composed of several different moving parts that work together. Some rope is made with outer coatings to prevent against wear resistance. While plastic coated cables are useful in theatre riggings and car towing, most rock climbers don’t bother with it, since the coating tends to rip off after a moderate amount of use.

All rock climbing wire rope needs some sort of surface protection. Since it is used outdoors so much, the rope is bound to come into contact with water at some point. And as we all know, water and metal are not a good combination, unless the metal is protected. So in order to prevent oxidization, which causes rusting, most wire rope is hot dipped in molten zinc. This is called galvanized cable, and it’s very durable, ware resistant and able to handle any bad weather. So if you’re feeling adventurous and have decided to rock climb, when you’re buying supplies, make sure you choose wire rope to keep you safe.

Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services