Tempered Glass: Achieving Higher Edge Strength

Tempered glass is relied in many applications where safety is a key concern. Some of these applications include vehicle passenger windows, rear windshields, phone booths, guard booth windows, patio furniture, decorative railing glass, basketball hoop backboards, racket ball court glass, and more. Not only is tempered glass four to six times stronger than annealed glass, but if it does break, it will fracture into small, less dangerous pieces while annealed glass has a tendency to shatter into large jagged shards. There two ways to temper glass: thermal tempering and chemical tempering. Thermal tempering uses an oven to heat the glass (usually to around 6200º Celsius) and then cooled quickly with evenly spaced high pressure blowers. This fast cooling causes high surface compression. The chemical tempering process, on the other hand, combines heat and a molten potassium salt bath, which causes atoms to exchanges places, making the chemical structure of the glass more crowded and thus, compressed. The compressed state, rather than high tension state, is what offers the desired strength of the glass.

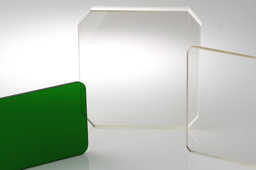

Photo Courtesy of S & S Optical

Photo Courtesy of S & S Optical

Chemical tempering is preferred in some cases as this process can be done on more complex shapes. It also creates glass that is up to twenty five times as strong as ordinary annealed glass. Unfortunately, the chemical process is more expensive to complete. Also, if chemically tempered glass does break it tends to break into larger, more dangerous, shards unless it is laminated. Whether the glass is thermally tempered or chemically tempered, any cutting, etching, edging or other fabrication operations should take place before tempering processes as these operations can cause strength reduction. Also, in both chemically and thermally tempered glass, the most vulnerable parts of the glass are at sharp edges of the plane, and if the edges become damaged then the strength of the whole plane of glass is compromised.

Photo Courtesy of S & S Optical

Photo Courtesy of S & S Optical

The vulnerability at the edges of the glass is due to the expansion that occurs during the tempering process. This expansion, whether caused by ion-exchange or fast cooling, pushes the sharp edges away from the body of the glass, which results in lower compression and higher tensile stress in the these areas. These negative aspects, however can be reduced if the edges are rounded rather than left sharp. This is why it is often recommended, if appropriate for the application, to round off sharp edges before the glass is subjected to any tempering processes. Improved edge strength improves the strength of the entire product, as each sheet or piece is only as strong as its weakest point. Acknowledging and understanding these weak points rather than ignoring them, allows industries to find ways of compensating for them or eliminating them entirely. That old saying “know thyself” applies here. Know your product, whether you are buying it or selling it, and make sure that that product is of the highest quality possible.

Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services