Choosing the Material for Hydraulic Cylinder Seals

Hydraulic cylinder seals play a crucial role in various types of machinery, and are usually constructed from thermoplastics, elastomers, or thermoplastic elastomers such as rubber, polytetrafluoroethylene, and polyurethane. When it comes to selecting the most appropriate material for the sealing element in hydraulic cylinders, there are several conditions that are important to consider. These include temperature, system pressure, media, surface roughness, system tolerances and sliding speed. Let’s take a look at the most important of these (Temperature, Pressure, Media, and Speed) and how they impact the decision of which material to use in order to get the best performance from hydraulic cylinder seals.

Working temperature is one of the most important aspects regarding the choice of the hydraulic seal’s material. Ideally, the working temperature would be around 50ºC for sealing elements and systems; however, application temperatures often reach 100ºC. in dynamic applications where there is direct contact between sealing elements and sliding surfaces, friction generated heat can effect the seals. It is important to ascertain the system temperature and make sure that it is lower than the working temperature of the sealing element. If applications require especially high temperatures, seals made from fluoroelastomers or polytetrafluoroethylene are recommended. Speed also increases friction force and decreases oil film thickness. For that reason, polytetrafluoroethylene is again recommended for applications that require high speeds.

System pressure is another huge determining factor when it comes to the material selection for these seals. It is recommended that shock pressures be taken into consideration when calculating system pressure as these are usually higher than normal working pressures. A recent demand for higher force has resulted in an increase of pressure in hydraulic systems overall, which in turn has resulted in new profiles with new engineering materials in sealing elements. Calculating the system pressure will guide you in selecting a sealing element with a corresponding working pressure. The media the sealing elements are being used in should also be taken into consideration. The viscosity of the media is affected by temperature as well as pressure (an increase in pressure increases viscosity while an increase in temperature decreases viscosity). The viscosity of the media can have negative effects, such as wearing, on sealing elements, so it is important to be aware of these relationships and interacting when pairing media and sealing elements.

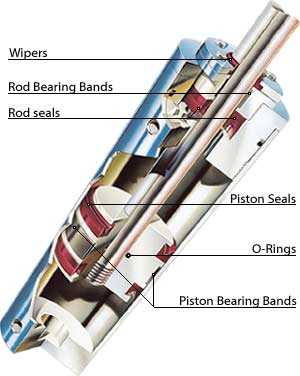

Photo Courtesy of Allied Metrics Seals & Fasteners, Inc.

Photo Courtesy of Allied Metrics Seals & Fasteners, Inc.

If you are in the market for hydraulic cylinder seals, it is important to evaluate the working variables discussed above and make an informed decision as to the most appropriate material for these seals. Most manufacturers of both seals and hydraulic cylinders provide application tables and guides with working temperatures, pressures, speeds, and media specifications to assist in the evaluation process. Get the most out of your cylinders and seals, make calculated purchases that will serve you in the long run.

Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services